ENGINEERED STEEL SYSTEMS

FOR MODERN CONSTRUCTION.

build better, faster and without TRADITIONAL CONSTRAINTS.

our mission

To modernize residential and multi-unit construction in Quebec and Ontario through precision-engineered light-gauge steel systems designed for speed, structural performance, and long-term durability.

We believe construction must evolve toward smarter, more sustainable building practices — reducing material waste, increasing structural lifespan, and utilizing fully recyclable steel systems that minimize environmental impact while maximizing efficiency.

Fortis exists to eliminate inefficiencies, reduce on-site uncertainty, and deliver engineered framing solutions that architects and developers can build on with confidence.

SCalable by design.

powered by technology.

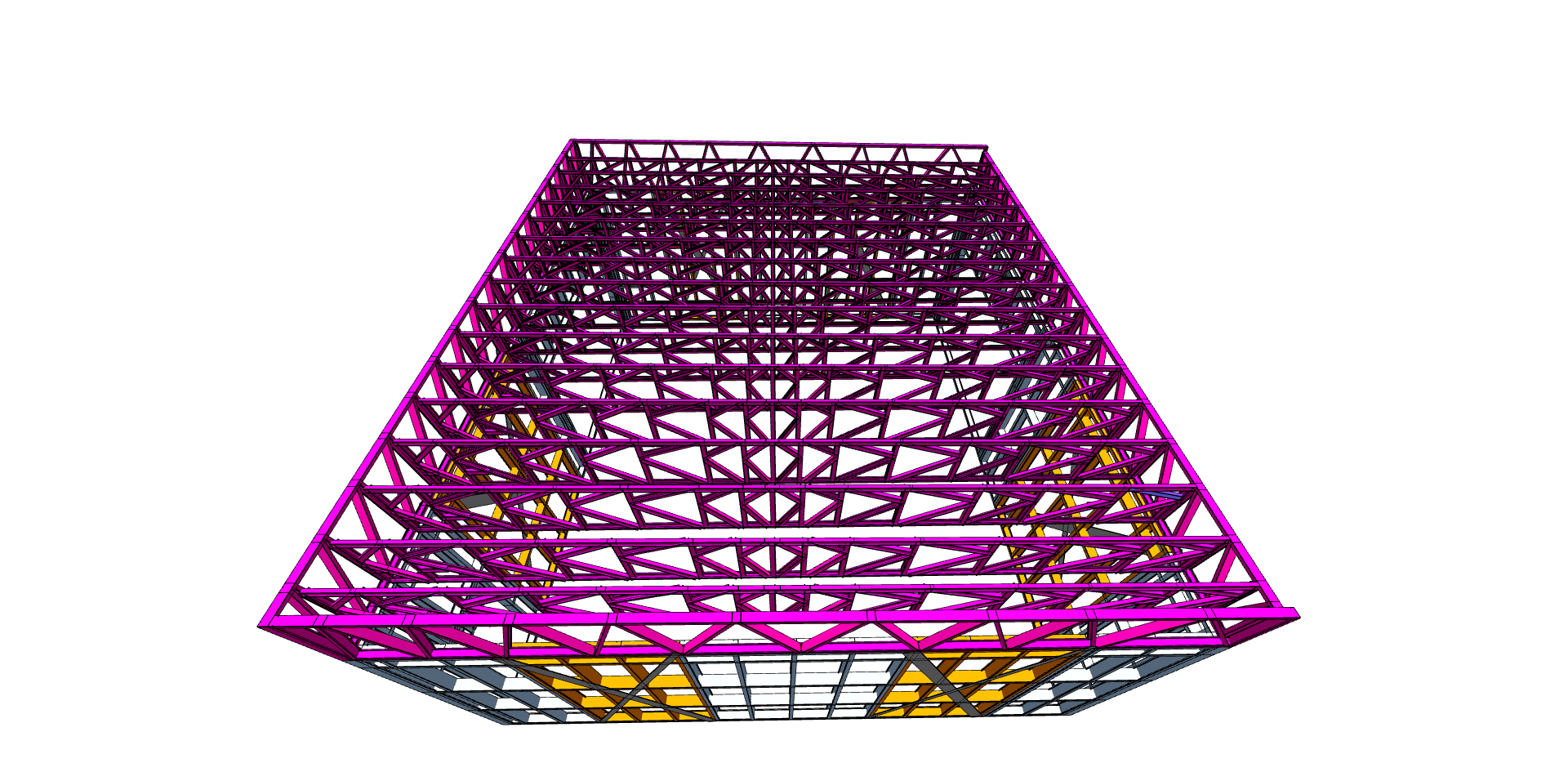

STEEL USAGE EFFICIENCY

We always look at how to use the right amount of steel — no more, no less. We deliver strong, efficient structures without unnecessary cost. Optimizing pounds per square foot is the ultimate goal for all projects.

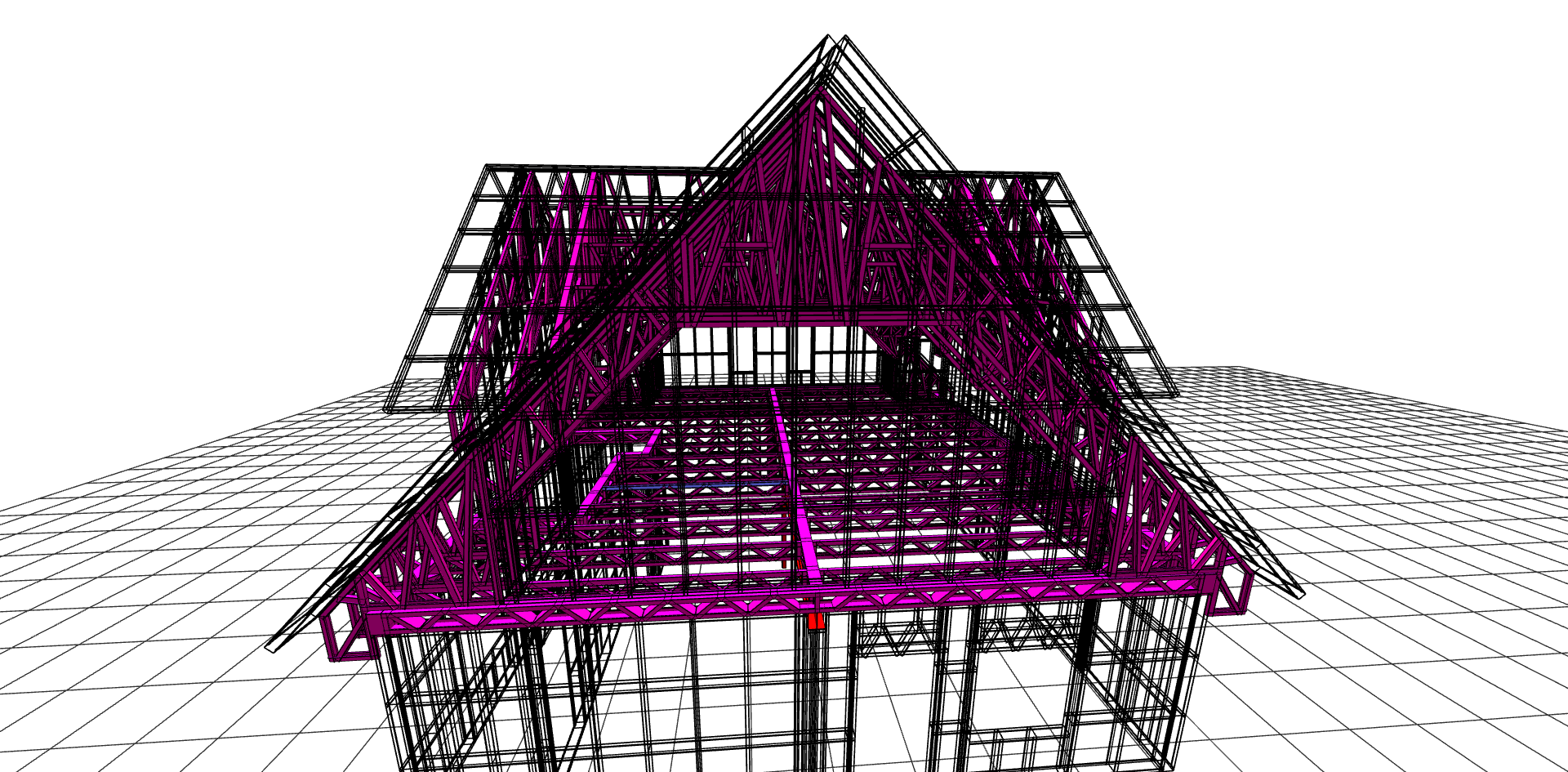

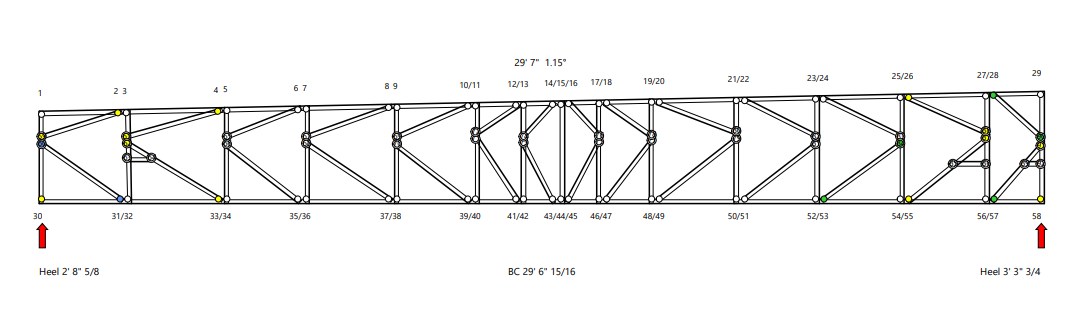

ONE STOP SHOP. COMPLETE STRUCTURE

Engineered roof trusses, wall panels, and full structural framing systems — modelled and manufactured under one roof for total coordination and accountability.

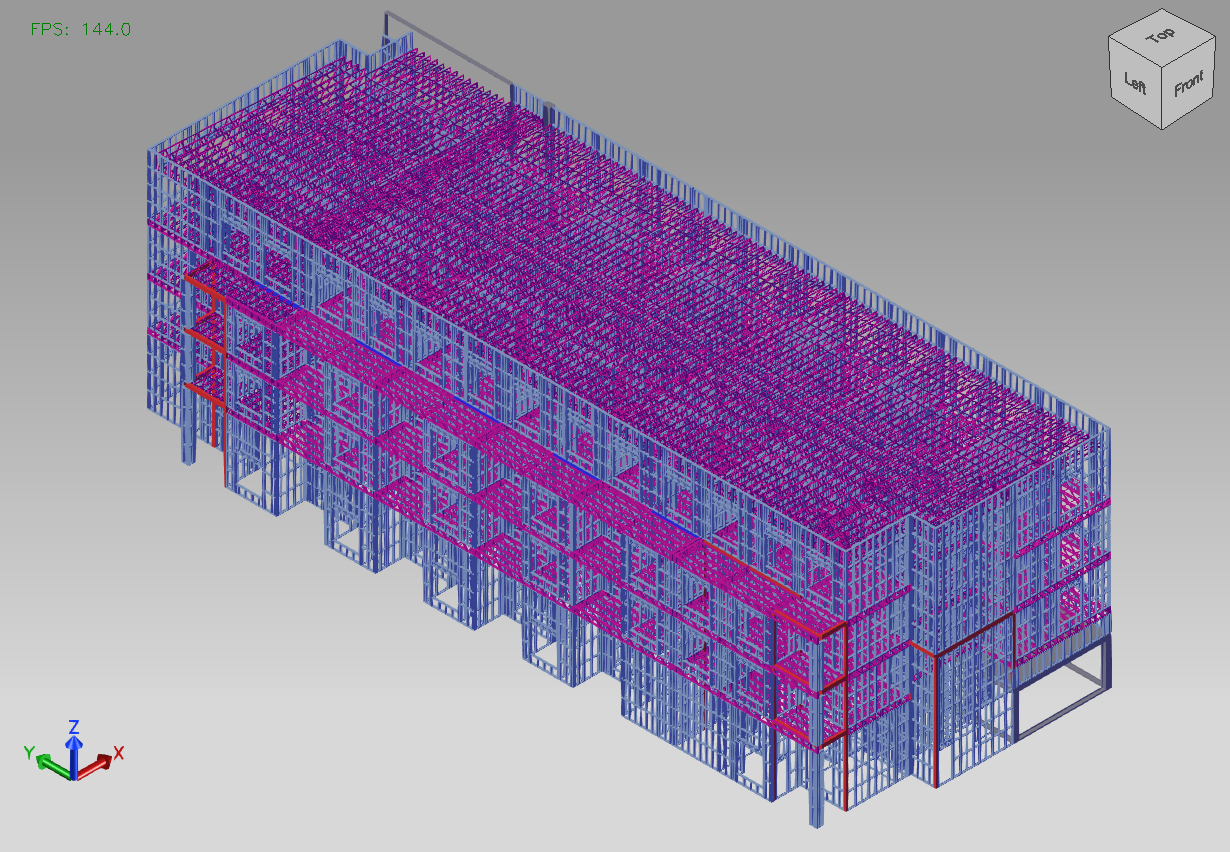

DIGITAL-TO-PRODUCTION CONTROL

We connect digital modelling directly to in-house production, reducing errors, accelerating timelines, and delivering predictable outcomes.

CANADIAN STEEL. ENGINEERED STANDARDS.

We use certified Canadian steel manufactured to meet recognized structural specifications, including CSA-compliant design standards. From structural members to bolts and connections, every component is selected to ensure strength, corrosion resistance, and long-term performance.

WHAT SETS FORTIS APART?

ENGINEERED FOR DEVELOPERS, Engineers & ARCHITECTS.

Digital-to-Production workflow

We model directly from your architectural drawings using advanced BIM tools, delivering production-ready framing systems aligned with engineering and manufacturing requirements.

• BIM-compatible

• Engineer-ready outputs

• Seamless transition to production

SPEED & COST EFFICIENCY

Prefab wall panels and trusses reduce on-site labor, shorten timelines, and increase ROI. Less labor. Less delay. More margin.

• Faster quoting, our system generates a precise steel usage report

• Reduced site delays and no improvisation

• Lower labor dependency

• Predictable scheduling

Precision manufacturing.

Our roll-forming systems deliver consistent, code-compliant framing — manufactured in-house for full quality control.

We use certified Canadian structural steel produced to recognized standards, including CSA-compliant design practices and ASTM material specifications.

• Certified Canadian structural steel

• 18–24 gauge cold-formed members

• G90 galvanized coating for corrosion resistance

• Designed in accordance with CSA S136

ONE SYSTEM. MULTIPLE APPLICATIONS.

Designed to scale across a wide range of building types:

• Mid-rise residential (primary focus)

• Multi-unit residential developments

• Load-bearing wall systems

• High-rise interior partition systems

• Single-family homes

• ADUs & secondary units

• Custom garages

• Light commercial structures

Manufactured using certified Canadian steel and precision roll-forming technology, every project is delivered with precision, durability, and coordinated production control.

WHY LIGHt GAUGE STEEL (LGS) ?

-

High strength-to-weight ratio –stronger than wood pound-for-pound

No warping, cracking, or shrinking over time

Engineered for dimensional stability to ensure an exact fit

Resistant to termites, mold, and rot

Designed for seismic and high-wind zones

-

100% non-combustible (doesn’t burn or contribute to fire)

Water resistant (no absorption or expansion when exposed to moisture)

Ideal for flood-prone and humid environments

-

Does not emit VOCs or toxins

Resistant to mold and mildew, helping maintain healthier indoor air quality

No chemical treatments required, unlike treated wood

-

Faster construction time enabled by prefabricated and cut-to-length structures

Less on-site labor (fewer errors & cleaner sites)

Lower maintenance costs over the long term

Minimizing foundation requirements and reducing transportation costs due to lightweight materials

-

100% recyclable with zero material waste

Longer lifecycle than traditional materials

Reduces replacement needs over decades

OUR PARTNERS

contact us

Ready to bring your project to life ? Fill out the form and we will get in touch with a free quote.